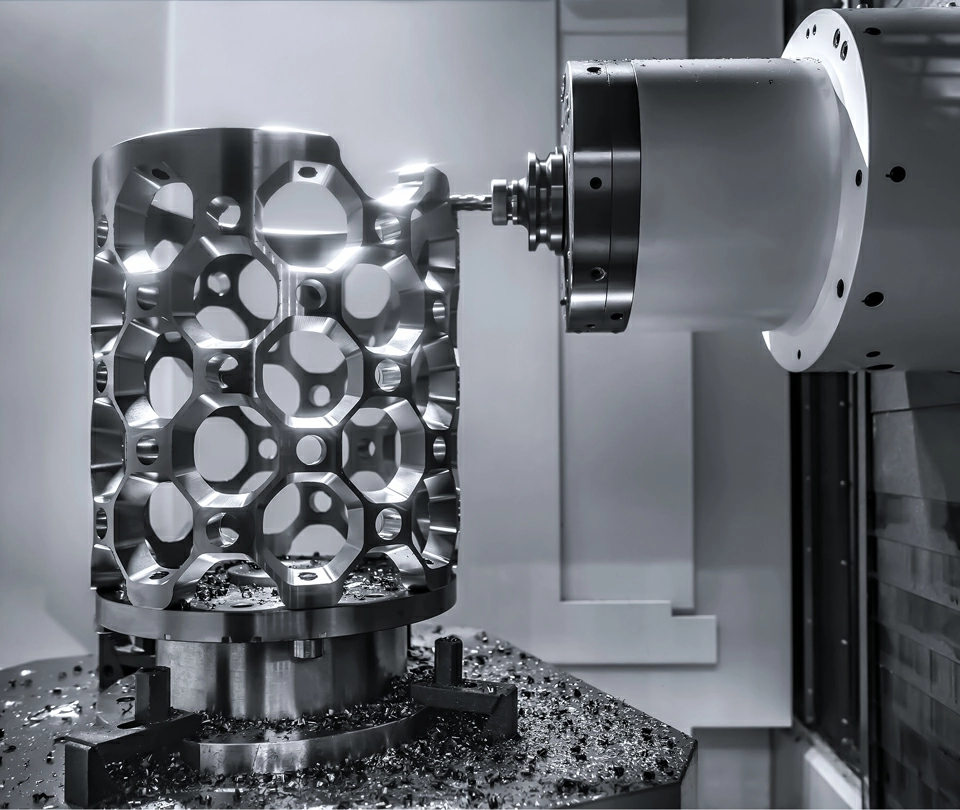

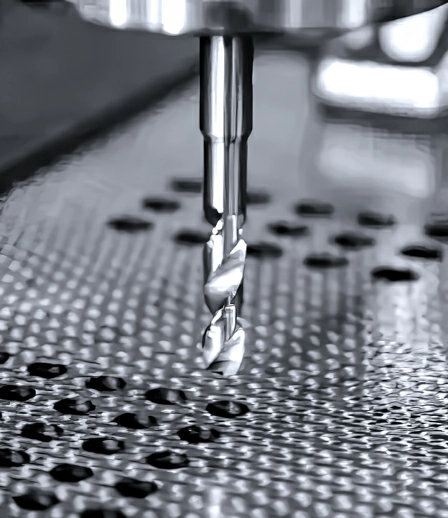

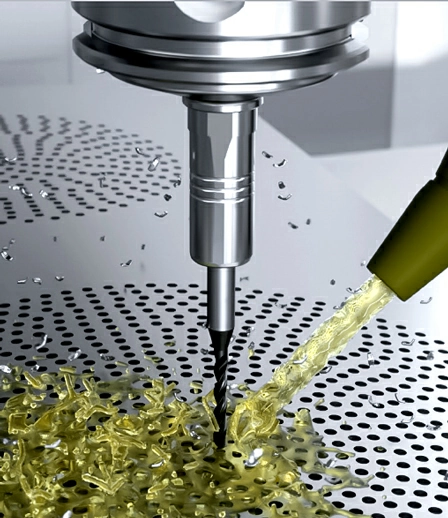

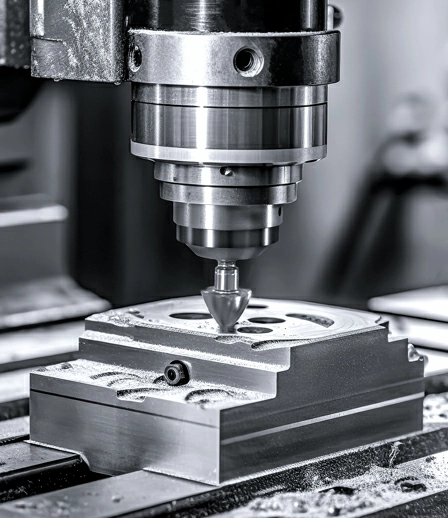

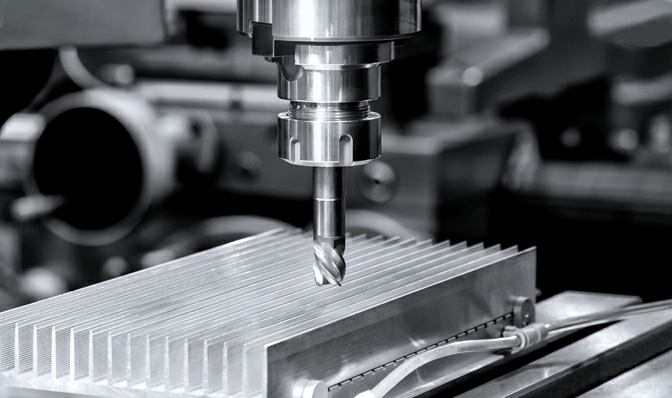

CNC Milling

CNC milling is a subtractive manufacturing process employing both 3-axis and 5-axis indexed milling techniques. This method precisely carves final parts from solid blocks of plastic and metal.

Learn More

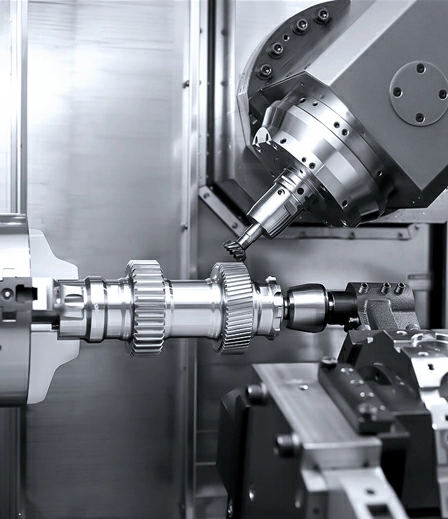

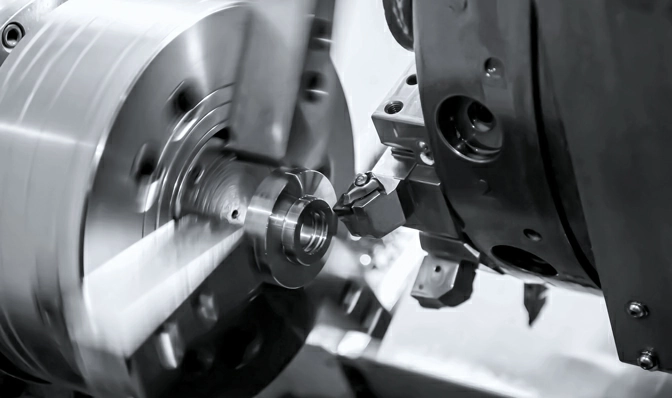

CNC Turning

CNC turning with live tooling seamlessly integrates lathe and mill capabilities, enabling the machining of parts with cylindrical features from metal rod stock.

Learn More