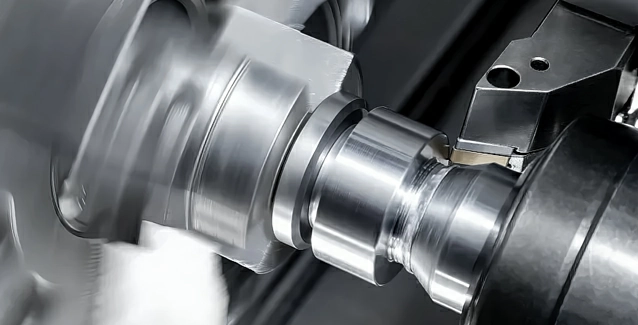

Precision Shaping with CNC Turning

CNC turning applies a cutting lathe to shape a part on a rotating workpiece. The workpiece spins on vertical or horizontal axes as the lathe moves around, ensuring precise, repeatable, and scalable production for parts with simple geometries and rounded or cylindrical shapes.

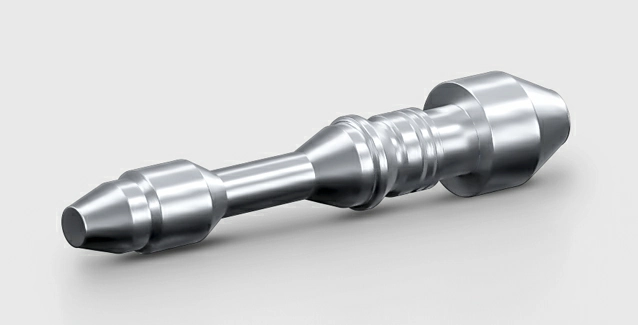

Ideal for High-Volume Production

Efficient and well-suited for high-volume production, CNC turning excels in creating parts with simple geometries and rounded or cylindrical shapes, offering a scalable solution for manufacturing.

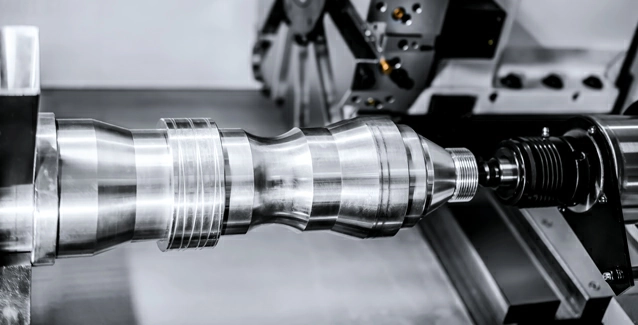

Efficient Symmetrical Manufacturing

CNC turning produces parts by mounting a blank on a rotating chuck and removing material with stationary cutting tools. Ideal for symmetrical parts, it delivers faster and more cost-effective results compared to milling.