Finishing & Post-Processing

Finishing and post-processing for CNC machined parts are straightforward. Upload your CAD files to our cloud platform, then choose the surface treatment or post-processing options you need. Once you approve production, we will implement your choices as part of your order.

What is CNC Machining Finishing and Post-Processing

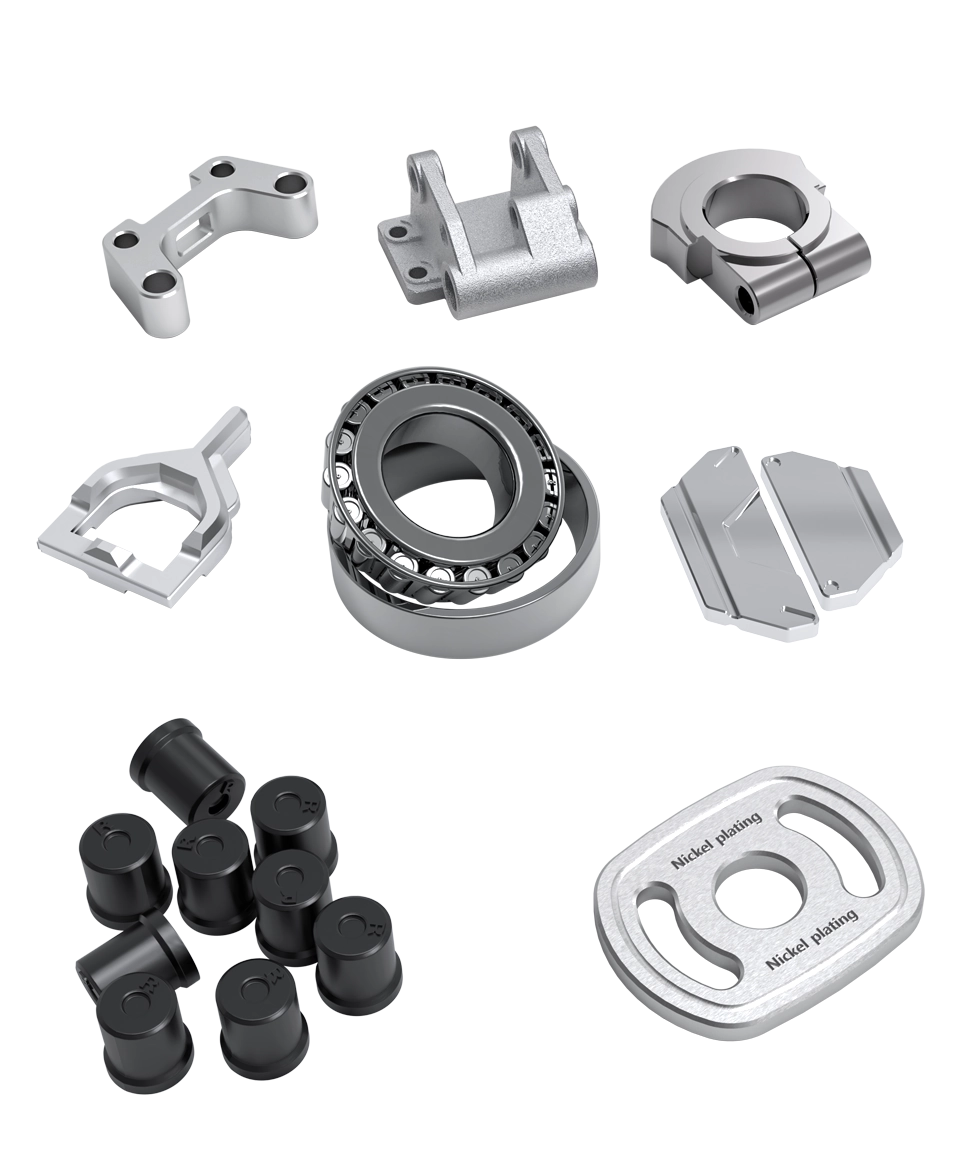

Crafted with automated precision and efficiency, CNC machined parts offer the flexibility for additional customization through various finishing and post-processing options. Collaborate with our skilled engineers to choose the optimal finishing solution for your CNC machining project, ranging from powder coating, bead blasting, painting, to intricate surface detailing.

Design Considerations

Maximum Part Size

| 3-axis Milling | 36 x 24 x 13 (inch) | 914.4 x 609.6 x 330.2 (mm) |

| 5-axis Milling | 16 x 16 x 16 (inch) | 406.4 x 406.4 x 406.4 (mm)* |

| Turning | 10 x 18 (inch) | 254 x 457.2 (mm) |

* Raw block weight limit up to 75 lbs.

Minimum Part Size

| 3-axis Milling | 0.1 x 0.2 x 0.2 (inch) | 2.54 x 5.08 x 5.08 (mm) |

| 5-axis Milling | 0.1 x 0.2 x 0.2 (inch) | 2.54 x 5.08 x 5 (mm)* |

| Turning | Ø 0.093 (inch) | Ø 2.36 |

| Feature | 0.0156 (inch) | 0.396 (mm) |

| Wall Thickness | 0.040 (inch) | 1.016 (mm)** |

* Minimum material thickness for plastic and steels: 0.125 in.

** Material and geometry dependent

Capabilities

| Linear tolerances | +/- 0.002 (inch) |

| Reamed holes | +/-0.0005 (inch) |

| Surface roughness | 63 (µ inch) |

| For parts under 1/10-inch thick | Flatness = 0.005 (inch) |

| For materials smaller than 6 x 12 inch | Parallelism = 0.010 (inch) |

| True position (two-plane and three-plane) | 0.015 (inch) |

| Profile of a surface | 0.015 (inch) |

Geometry Limitations

| Knife-edge features. |

| Parts drafted on both internal and external walls. |

| 5-axis parts with cavity depth exceeding 6 inches. |

Finishing & Post-Processing Materials

Metals