CNC Milling Service

Utilize our CNC milling services to efficiently craft industrial-grade parts and components with automated speed and precision.

What Is CNC Milling

01

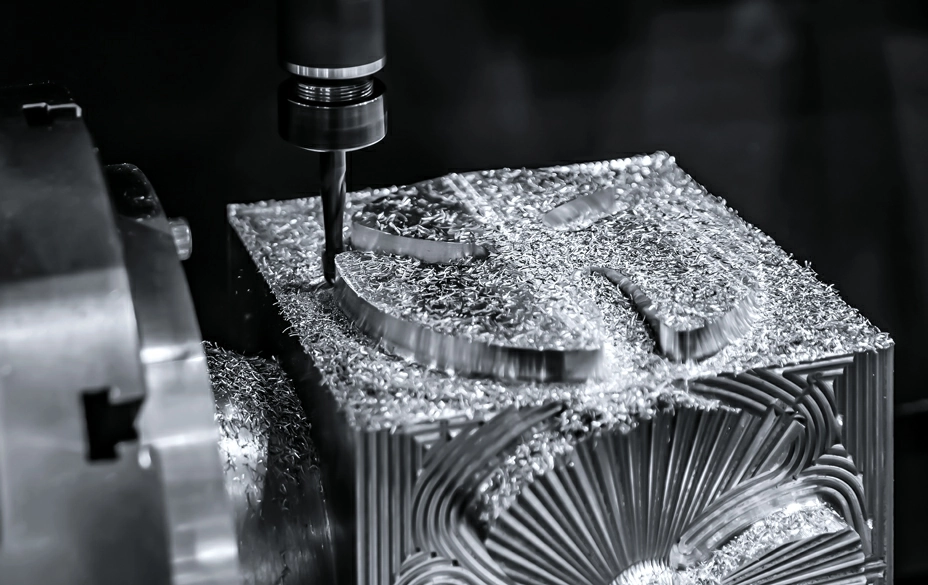

Precision Shaping Process

Computer-controlled subtractive machining process, precisely shapes custom-designed parts by removing material from a stationary workpiece using rotating cutting tools. The process begins by fixturing a block of metal or plastic material inside the CNC mill.

02

Efficient Carving

Through G-code, our CNC machines efficiently carve out parts from the raw material block along multiple axes.

03

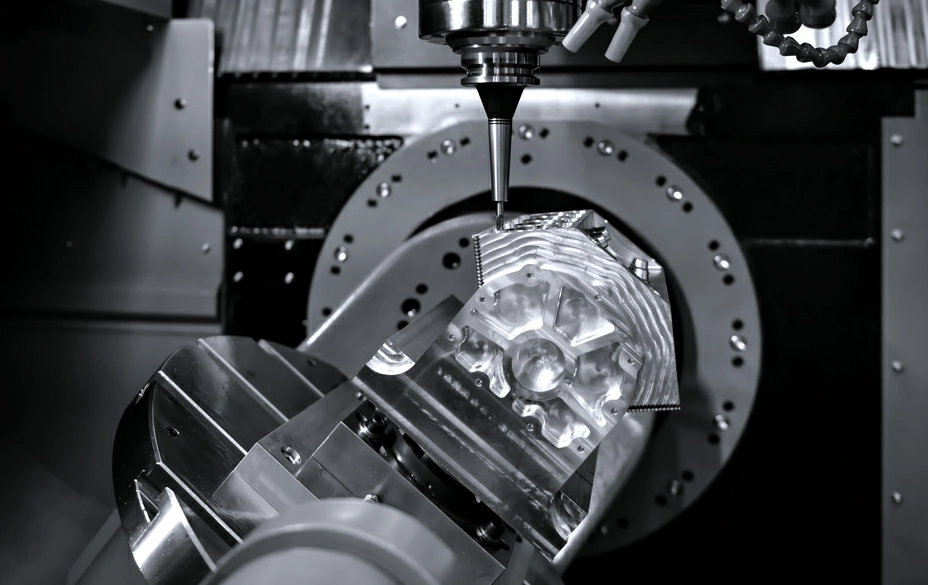

Maximum Efficiency with Diverse Toolsets

Equipped with diverse toolsets, our 3- and 5-axis CNC machines ensure maximum efficiency, offering a reliable solution for the fabrication of intricate shapes.

Design Considerations

CNC Milling Materials

Metals

CNC Milling Applications

Rapid prototyping

Provides a visual and tactile representation of a product or part, allowing assessment before engaging in more expensive production processes.

Medium-to-High Volume

Especially advantageous for large-scale manufacturing, providing automated speed and cost advantages.

Hybrid Manufacturing

CNC milling extends beyond metal applications; it seamlessly accommodates machining for molded and 3D printed parts.

Precision Tooling

Craft intricate parts featuring complex cuts and varying angles through the use of a diverse set of cutting, drilling, and lathing tools.

Finishing & Post-Processing

Finishing & Post-Processing

Finishing

Precision is paramount in complex machining, and our commitment goes beyond the workshop. Our applications engineers offer expert design feedback to ensure your parts not only meet but exceed expectations.

Post-Processing

Streamline your custom parts procurement with over 22 surface finishing options. Opt for bead blasting, anodizing, or powder coating to enhance the quality and aesthetics of your components.